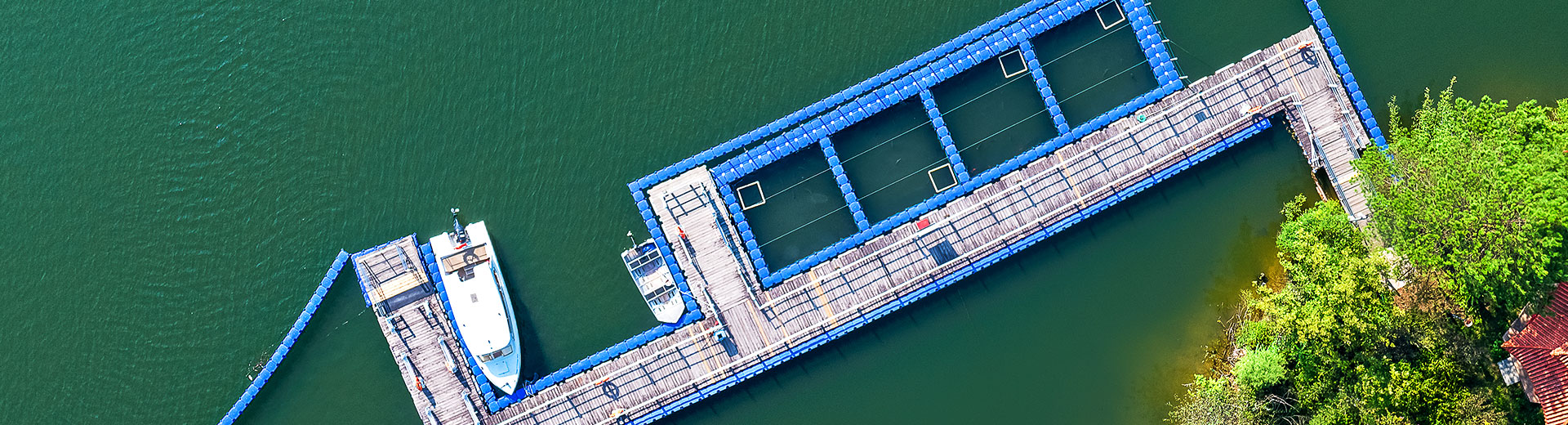

Before water withdrawal, the Company conducts water use analysis and assessment to analyse the current water resources development and utilisation situation in the watershed or region where the project is located, including the rationality of water use, the impact of water resources development and utilisation on water resources conditions and other resident with water withdrawal, and the water resources protection measures. We update the results of our water risks assessment annually to find out changes in water risks in the regions/water areas in which we are located, in order to formulate effective measures to reduce risks and ensure that the water resources are able to support the Company’s long-term operations and the common development of all stakeholders.

We assessed the annual water risks at our operation sites using AqueductTM Tools, a tool developed by the World Resource Initiative (WRI). It covered quantitative physical risks (e.g. baseline water stress, meteorological hazard impacts) and qualitative physical risks (water quality impacts), as well as regulatory and reputational risks.