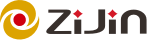

A chart of Kamoa-Kakula’s quarterly copper production since first production in May 2021.

In the second quarter of 2023, the Kamoa-Kakula copper complex, a joint venture between Zijin Mining and Ivanhoe Mines in the Democratic Republic of Congo (DRC), produced a record 103,786 tonnes of copper in concentrate, a quarter-on-quarter increase of 11%.

Aerial view of the Phase 1 and 2 concentrators in the foreground, overlaid with a rendered 3D rendering of the adjacent smelter site in the background.

Debottlenecking programs for Phase 1 and 2 of Kamoa-Kakula’s concentrators have been completed, and the concentrator plants are now operating at an increased throughput rate of 9.2 million tonnes per annum. Phase 1 and 2 concentrators milled approximately 2.2 million tonnes of ore in Q2, at an average feed grade of 5.2% copper. Average copper recoveries remained stable, at 87.2% in the second quarter.

The project’s Phase 3 expansion, which consists of two new underground mines known as Kamoa 1 and Kamoa 2, and a new concentrator plant with a capacity of 5 million tonnes per annum, is well on track for first production in the fourth quarter of 2024. After Phase 3 commences production, Kamoa-Kakula will have a total processing capacity of more than 14 million tonnes per annum, which will make it the fourth-largest copper mining complex in the world.

Steel erection of Kamoa-Kakula's direct-to-blister flash furnace and the electric slag cleaning furnace.

The Phase 3 expansion also includes the refurbishment of turbine #5 at the Inga 2 hydroelectric power station. The turbine will supply an additional 178 megawatts of clean hydropower to the national grid of the DRC, which is sufficient to meet the power requirements of the Phase 3 concentrator and the direct-to-blister flash smelter. It will also provide spare capacity for future expansions. Kamoa-Kakula’s smelter will produce 99.7% pure blister anode copper with one of the world’s lowest carbon dioxide emissions per tonne of copper produced.

All figures are on a 100% project basis and metal reported in concentrate is before refining losses or deductions associated with smelter terms.

Translator: Jian Reviser: Li Yuanxing Editor-in-Chief: Wang Jie

About Zijin Mining

Zijin Mining is a leading global metals and mining company and one of the world’s largest producers of gold, copper, and zinc. The company has more than 30 large-scale mining operations and projects across 19 countries on 5 continents. Leveraging strong in-house research, engineering, and development capabilities, Zijin maintains high operational efficiency and low costs in both acquisitions and operations. This enables the company to be an industry leader in value creation, underpinned by its philosophy of pursuing development for all and sustained by superior environmental, social, and governance performance. Zijin’s shares trade on the Hong Kong Stock Exchange (HKEX: 2899) and the Shanghai Stock Exchange (SSE: 601899).